Holmen, WI—A new food manufacturing plant in Wisconsin is making traditional process cheese, as well as alternative dairy products that target a growing, yet obviously different, segment of consumer.

Holmen Cheese is the newest, and one of the most innovative, food manufacturers to impact the cheese industry; answering a niche for food products perceived as healthier and more environmentally sustainable than the traditional cheese market.

Established in 2020, Holmen Cheese is a 100,000-square-foot, state-of-the-art production facility, which promises to create, produce and deliver customized, high-performance solutions for cheese and cheese alternative markets worldwide.

Holmen Cheese is a custom formulator of process cheese and of products without a standard of identity, which includes plantbased cheese for the industrial, food service and retail markets.

As a custom formulator, the company’s product line is virtually endless.

“We market ourselves as an innovative dairy solutions provider,” said Jeff Fowler, CEO of Holmen Cheese. “That just means we take companies’ needs and turn them into reality.”

All of Holmen Cheese’s production is private label.

“We want to play in all the arenas,” Fowler said. “Dairy cheese isn’t going away, but we also know that’s not where the ultimate growth is for us.”

He said that, for his company, dairy cheese isn’t where the high margin products are either.

“We will continue to make process cheese and dabble in that cheese world, but we’re an imitator of those products for a different marketplace. We’ll do it and do it well, but what’s really going to make us grow and be successful is that innovative side,” Fowler said.

“Making products better than others and coming up with the solutions our customers can’t make themselves.”

We are going to see what the demand is and where it is, Fowler said. We’ll make those decisions as we mature.

“We do not intend on being real strong in standardized cheeses. That’s not our strength,” Fowler said. “We will produce about 40 to 60 million pounds of high-quality process cheese annually over the next few years.”

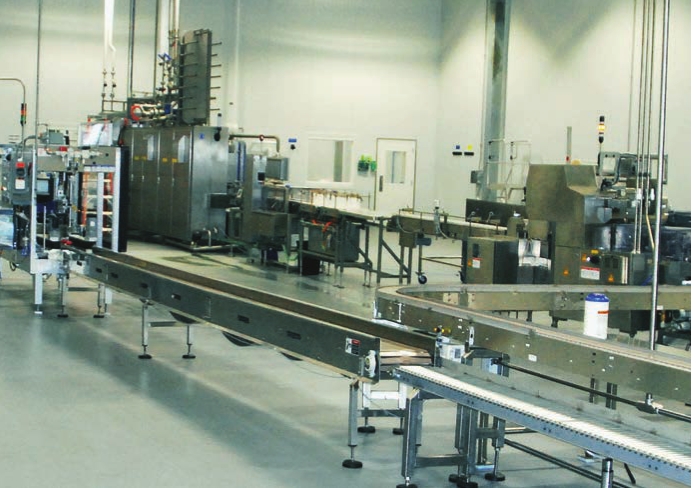

Kelley

Supply played a major role in the design of Holmen Cheese, said Jerry

Fowler, CEO. Above, Kelley Supply intergrated Holmen Cheese’s Natec

USA’s individually wrapped slice line. The company is focusing on non-standardized cheeses designed and engineered for the expanding non-dairy marketplace.

“Plant-based cheese is a very hot item,” Fowler said. What the company is making in process cheese over the next couple of years is what they aspire to do in the plant-based cheese in next five to 10 years.

The company would like to balance the production in five years but invert production to an 80/20, plant-based over process cheese in 10 years.

“As far as plant-based we are just scratching the surface,” Fowler said. “This year we are estimating four to six million pounds annually. We expect we will be 10-fold that amount in less that 10 years.”

Although there is an overlap in equipment used to manufacture and package Holmen’s dairy and plant-based cheese, a significant investment was made is specialized systems unique to plant-based offerings, Fowler said.

“Kelley Supply was instrumental in designing and integrating the production and packaging areas of the plant,” Fowler said. “This is a state-of-the-art plant, Kelley’s know-how was vital in the smooth transition throughout the process.”

Besides, Kelley Supply, Loos Machine’s cookers and hoppers are used to make the products,

while Natec USA LLC’s filling and IWS lines are used in the packaging. A

Philquip cutter is used to reduce product prior to cooking. Other

necessary and more proprietary equipment is used to perfect the

company’s unique recipes.

Plant -Based Cheese Market

According

to the Plant Based Foods Association (PBFA), US retail sales of

plant-based foods grew 11.4 percent in 2019, bringing the total

plantbased market value to $5 billion.

The

growing plant-based dairy alternative categories are growing even

faster as new plant-based dairy items are introduced. In 2019,

plant-based yogurt grew 31 percent; plantbased cheese grew 18 percent,

plant based ice cream grew 26 percent; and plant based butter grew 5

percent, according to the PBFA.

Across

the board, all categories of plant-based foods showed growth with the

highest rates in creamers, sauces, and dips. This illustrates new

opportunities for brands looking to expand their portfolio, the PBFA

said.

Dave Kelsey, vice president of sales at Holmen Cheese, says plant based foods are not a fad; they are a movement.

“I

think plant-based foods are going hand-in-hand with society,” Kelsey

said. “Consumers are looking for and moving to foods with sustainability

and things that are green. People are being driven towards a healthier

lifestyle, getting rid of the transfat, getting rid of dairy because

they are lactose intolerant.”

A

selectarian is usually used to describe those who are primarily

vegetarian yet eat meat and fish on occasion, according to the New York Times. Others use the word flexitarian to define this person.

Kelsey

said that Holmen Cheese market research found that, for the most part,

the flexitarian represents 75 to 80 percent of the total buy on our

plant-based opportunities. True vegetarians represent 20 percent of the

buy.

“We’re trying to

make a plantbased cheese product that is universally accepted to

vegetarians and flexitarans,” Kelsey said. “The flexitarian feels it is

something that is going to be good for them, have health benefits, but

can’t accept it as a diet 365 days a year.”

Plant-Based Cheese Hurdles

Up until now, both Fowler and Kelsey admit the biggest problem with plant-based food products have been the taste.

“Vegans

will buy the product. Period. However, flexitarians still demand good

taste,” Kelsey said. “We’ve found out, if they can’t find good tasting

products, we may lose them forever.”

This has support of the NPD Group and Darren Seifer, food and beverage industry analyst.

“First

and foremost taste is king when considering entering the plant-based

foods category,” Seifer said. “Attributes such as health and convenience

go far to drive consumption, but if the flavor profile falls below

consumers’ expectations, then the product will likely have a short run.”

Besides taste, mouthfeel and functionality needed to improve.

With

the introduction of the Impossible Burger a few years ago, Fowler

believes the plant-based industry is on the verge of catching up with

consumer demand for all products.

“It’s

going to be part of the evolution,” Fowler said. “Plant-based cheese

will almost certainly piggy back on the success of other foods like

plant-based meats. That’s going to open it up. Better tasting

plant-based burgers, pizza, sandwiches, that’s where it will tip.”

“Whether

it’s marketing a plantbased burger that reproduces the meat-eating

experience or a dairy alternative that has the taste and texture of

milk, consumers now have substitution without sacrifice,” NPD’s Seifer

said.

Kelsey said that plant-based cheese quality currently lacks any consistency.

“It

is all over the board. Many companies who make plant-based cheese are

still using the recipes they started out with,” Kelsey said. “They are

driving other companies to get better.”

A

plant-based cheese may have 3 to 5 percent protein value where

traditional cheese may have 20 to 25 percent protein, Kelsey admitted.

“What

buyers want to see right now, is getting more protein value in the

plant-based cheese,” Kelsey said. “Adding protein to plantbased foods is

a challenge because the proteins that are currently available to us are

often dark in color and have very distinct flavors and are not in tune

with what we are trying to do.”

Fowler said this too is improving and certain protein suppliers have come a long way.

“They are getting a lot better,” Fowler said. “I think plant-based is really in its infancy right now. It’s in the wild west.”

Fowler

said as Holmen Cheese and other companies keep improving their

products’ attributes, the consumer will ultimately decide where the

market ends up.

“There

are a lot of people that want plant-based cheese, there are a lot of

people that have tried it, and a lot of people hoping it works,” Fowler

said. “We are improving the taste, getting the performance, the

functionality that the consumer wants, whether it would be shredding for

pizzas or melting on that burger.”

Once

we can do the sheer volume of making a good tasting plant-based cheese,

then the price can come down, Fowler said. If a natural cheese was

$2.00 per pound, you can expect the plantbased cheese to be around

$10.00 per pound, he said.

“We will continue

to make process cheese and dabble in that cheese world, but we’re an

imitator of those products for a different marketplace.

—Jeff Fowler, Holmen Cheese

“At that price, only

the true vegetarians are buying it,” Fowler explained. “If we nail the

taste, get a really good functional product enabling us to amp up

production a little, then we can get the price down to around $3.00 a

pound, and that’s when the gates open.”

The Products At Holmen Cheese

The

non-dairy cheeses made at Holmen Cheese are all GMO-free, use only

natural products without the traditional preservatives, says Dave

Kelsey.

The goal for Kelsey is clean flavors that are not very strong.

“We

are making flavors that are perceived dairy notes, albeit not dairy,”

Kelsey said “They are very clean and point you in the direction of

traditional dairy products.”

He said the products will continue to evolve.

“We

celebrate that. We celebrate the tools we have to work with getting

better, and us being able to use and engineer better plant-based cheese

as a result of those better tools.”

Holmen

Cheese happily works in the industrial, foodservice and retail segments

of the industry. However, most of the current production is going into

the industrial segment. Kelsey said new offerings being developed,

combined with commissioning new equipment, will diversify and expand

that customer base.

“We

are increasing production of 5-pound loaves that targets the

foodservice industry,” Kelsey said. “Our shred line is coming online for

foodservice operators and retail stores. Our IWS line is growing for

retail and foodservice as well. We’ll be spreading production around

pretty quick.”

The

company also has a drying line and makes a plant-based cheese for

Parmesan crisps or to make other traditional Italian cheese powders for

the Italian foodservice industry.

“We

are extremely confident in the product we are making,” Kelsey said.

“It’s the best-tasting, most functional product in the marketplace.

Plant-based Mozzarellas for pizza applications, sauces and spreads,

cream cheeses, plantbased Cheddars and American styles for burgers, Blue

cheese, Gouda, Provolone, Edam, we are totally flexible in modifying

them for any plant-based marketplace.”

Confirmation Of Efforts

Holmen Cheese is a privately-held ownership with three majority owners and two minority owners.

A

few of the workers have small stakes in the company, Fowler said. And

many of the owners have cheese industry experience, but all of them have

food industry experience.

“I

guess many on the ownership team look at the cheese industry and see,

as we all do here, an opportunity or an untapped slice of the changing

marketplace,” Fowler said. “That there is a missing piece there.”

Fowler said his company has talked with big, international food marketers about plant-based foods.

“Their interest puts a stamp on what we are doing. They know it’s going to be a large piece of the pot,” Fowler said.

But those big food marketers can’t move as quickly as we can so they partner with groups like Holmen Cheese, he said.

“If

you are one of the first ones making a good product, with solid

management and infrastructure, we think that company is going to grab a

majority of the market share,” Fowler said.

There

are a lot of companies that want to get into the market, but they don’t

want to make it, they just want to market it, he said.

“The marketers will have a big responsibility in selling the product and driving its growth.”

He

said the marketers realize the flexitarians are not just looking at the

flavor, they want a replenishable product. They are looking at the

bigger picture, not just looking at the end product.

Millennials are the top consumers of plant-based meat alternatives, according to a

recent study from The NPD Group. This generational group has adopted

plantbased meat alternatives as a way to indulge sensibly while

addressing their long-term health goals and animal treatment concerns.

Gen

Xers are also a core consumer group of plant-based meat alternatives

and, because many in this group are parents of Gen Zs, they raised their

Gen Z children on plant-based beverages and foods, the NPD study found.

Baby Boomers are decelerating their consumption of plant-based meat

alternatives but are the top consumers of plant-based dairy

alternatives.

Since

the core consumer groups for plant-based dairy and meat alternatives are

younger, NPD forecasts that plant-based foods, to varying degrees, do

have staying power. NPD’s study also found that plant-based food

consumption is not about rejecting traditional protein sources as about

90 percent of plant-based users are neither vegetarian nor vegan, noting

that consumers want options.

Fowler

said that it’s more of a demographic than a region and the millennials

are growing up with plant-based foods and will come to seek it out more

in the future.

“I

think if you look at the numbers of where the products are sold, you’ll

probably find sales are higher on the coasts,” Fowler said. “But that

doesn’t mean there is nothing in the middle. We’ll probably see it in

industrial use, more in the middle of the country.”

Fowler also points to the grocery stores having dedicated entire areas to plant-based foods.

“There

is a limited amount of space in a grocery store, you look at the amount

of that given to plantbased, as a relatively new category, it’s

confirmation of the shift, while some other category is losing out,”

Fowler said.

And that category may be dairy, he said.

Right, wrong or indifferent, there’s definitely a marketing push against dairy, Fowler said.

“If

enough people believe that, ‘if I can get something that tastes like

dairy but isn’t dairy, I’d eat that all the time’ attitude, plantbased

dairy products, while never replacing dairy, will continue to grab its

market share,” he said.

As

food manufacturers, Holmen Cheese believes they are poised to fill the

flexitarian’s attitudes for plant-based dairy products.

“We

made a huge investment to build a world-class facility with

world-renown talent, and we’ve checked all the requirements for quality,

functionality and flavor,” Fowler said. “We’re pretty darn confident

that Holmen Cheese, is perfectly positioned to fill the needs of the

marketplace,” Fowler said.

For specific product line information or more information on the company, visit www.holmencheese.com.